Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

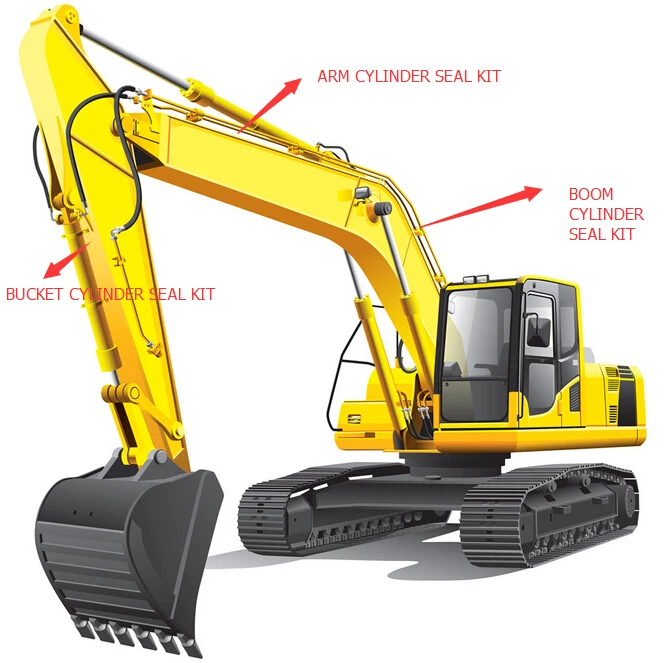

What is an oil seal repair kit?

An oil seal repair kit typically includes all the necessary components to repair or replace a damaged or worn oil seal. This may include a new seal, a seal installer tool, and any necessary gaskets or o-rings. The specific components included in a repair kit may vary depending on the application and the manufacturer, so it's important to choose a kit that is designed for your specific equipment.

Arm Cylinder Seal Kit: An arm cylinder is a hydraulic cylinder that extends and retracts the arm of an excavator or other heavy equipment. An arm cylinder seal kit contains the seals and other components needed to repair or replace the seals in the arm cylinder. The seals in an arm cylinder seal kit are designed to withstand the pressure and wear and tear of the arm cylinder, and they are typically made of materials like polyurethane or nitrile rubber.

Boom Cylinder Seal Kit: The boom cylinder is a hydraulic cylinder that extends and retracts the boom of an excavator or other heavy equipment. A boom cylinder seal kit contains the seals and other components needed to repair or replace the seals in the boom cylinder. The seals in a boom cylinder seal kit are designed to withstand the pressure and wear and tear of the boom cylinder, and they are typically made of materials like polyurethane or nitrile rubber.

Bucket Cylinder Seal Kit: The bucket cylinder is a hydraulic cylinder that controls the movement of the bucket in an excavator or other heavy equipment. A bucket cylinder seal kit contains the seals and other components needed to repair or replace the seals in the bucket cylinder. The seals in a bucket cylinder seal kit are designed to withstand the pressure and wear and tear of the bucket cylinder, and they are typically made of materials like polyurethane or nitrile rubber.

| Seal Kits Catalog | Models Cases |

| Bucket Cylinder Seal Kit | SH210-5 Bucket Cylinder Seal Kit |

| ZX330-6 Bucket Cylinder Seal Kit | |

| SK480 Bucket Cylinder Seal Kit | |

| CAT329D Bucket Cylinder Seal Kit | |

| Other Models | |

| Boom Cylinder Seal Kit | ZX330-6 Boom Cylinder Seal Kit |

| SK480 Boom Cylinder Seal Kit | |

| SH210-5 Boom Cylinder Seal Kit | |

| Other Models | |

| Excavator Bucket Cylinder Seal Kit | PC200-8 Excavator MCV Seal Kit |

| PC300-7 Excavator Bucket Cylinder Seal Kit | |

| Other Models | |

| Boom Cylinder Seal Kit | SK480 Boom Cylinder Seal Kit |

| ZX330-6 Boom Cylinder Seal Kit | |

| SH210-5 Boom Cylinder Seal Kit | |

| Other Models | |

| Control Valve Seal Kit | PC300-7 CONTROL VALVE SEAL KIT |

| Other Models | |

| Swing motor seal kit, master cylinder seal kit | etc. |

Why use an oil seal repair kit?

There are several reasons why you might choose to use an oil seal repair kit instead of replacing the entire component or system. For one, repair kits are often more cost-effective than replacing an entire part or system. Additionally, repairing a single component can be faster and less disruptive than replacing an entire system, which can be especially important in production environments where downtime can be costly.

What are the benefits of using an oil seal repair kit?

In addition to the cost and time savings, there are several benefits to using an oil seal repair kit. First and foremost, repairing or replacing worn or damaged oil seals can help prevent leaks and other issues that can lead to equipment failure. This can improve the reliability and lifespan of your equipment, as well as reduce the risk of costly repairs or replacements down the line.

Additionally, using an oil seal repair kit can help ensure that your equipment is operating at peak efficiency. When seals are worn or damaged, they may allow lubricants or other fluids to leak out, which can reduce the effectiveness of the lubricant and cause unnecessary wear and tear on other components. By repairing or replacing the seal, you can help ensure that your equipment is running smoothly and efficiently.

How to use an oil seal repair kit?

Using an oil seal repair kit typically involves removing the damaged or worn seal and replacing it with a new one. The specific steps involved may vary depending on the equipment and the kit being used, so it's important to follow the manufacturer's instructions carefully. In general, the process may involve removing any necessary components to access the seal, removing the old seal, installing the new seal using the provided installer tool, and reassembling the equipment.

It's worth noting that while oil seal repair kits can be a useful tool for repairing and maintaining equipment, they may not always be the best solution. In some cases, the damage to the seal may be too extensive or the equipment may be too old or worn to justify repairing just the seal. In these cases, it may be more cost-effective and efficient to replace the entire component or system.

In conclusion, oil seal repair kits can be a valuable tool for repairing and maintaining equipment, helping to prevent leaks and prolong the life of your equipment. By choosing the right kit and following the manufacturer's instructions carefully, you can help ensure that your equipment is operating at peak efficiency and minimize the risk of costly downtime and repairs.